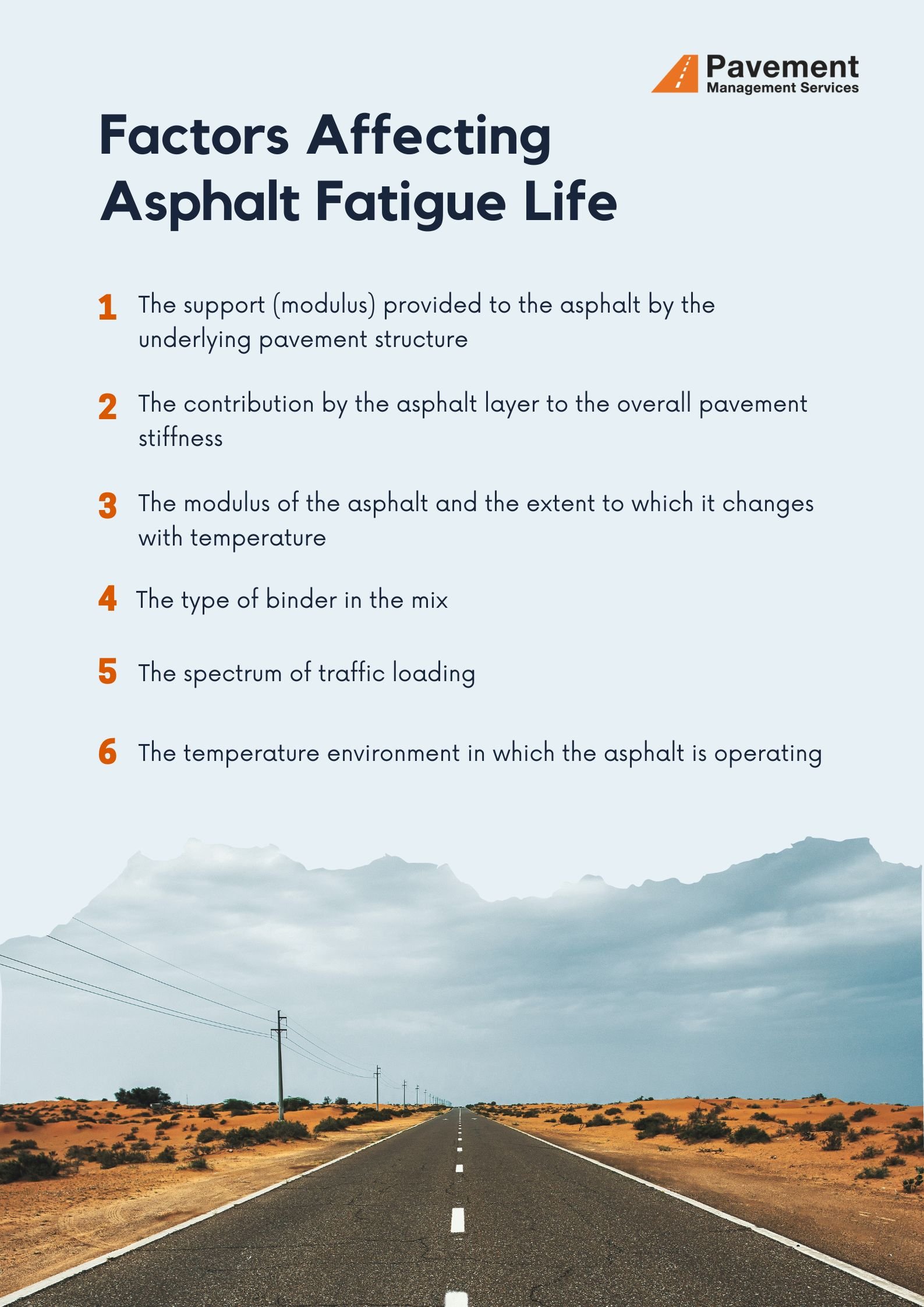

Factors affecting asphalt fatigue life

In asphalt pavements, there are certain factors that can influence a pavement’s ability to withstand fatigue, including:

pavement structure (thin pavements or those without strong underlying layers are more likely to show fatigue cracking than thicker pavements or those with a strong support structure)

age of the pavement

the materials used in construction

Additionally, there are several factors that can affect asphalt fatigue life.

Effect of support provided by the underlying structure

Increasing the stiffness of the pavement substructure supporting it, will extend the fatigue life of an asphalt layer. While this is generally true, it implies that this support remains throughout the life of the asphalt. However, this may not be the case if, for instance, the asphalt is placed directly into a stiff cemented layer, and this develops fatigue cracks earlier on in the pavement’s life. This greatly decreases the support provided and cause high level strains in localised areas in the asphalt (above underlying cracks).

If asphalt is put on granular material, the level of support to the asphalt will rely on the contribution made by the asphalt layer to the pavement stiffness – the greater this contribution, the lower the level of support provided. This is because the modulus of granular material is dependent on the level of stress it is subjected to, i.e. the lower the stress, the lower its modulus.

Effect of the asphalt layer’s contribution to overall pavement stiffness

Because the fatigue life of the layer relies on the levels of tensile strain occurring in the layer from traffic loads, and because these strain levels decrease as the asphalt modulus increases, for the ‘controlled stress’ situation the fatigue life increases by increasing the asphalt modulus.

As the contribution by the asphalt layer to the overall pavement stiffness increases, the bottom of the asphalt layer will begin to experience tensile stress and strain. If the asphalt’s contribution to the overall pavement stiffness is still generally small, the level of strain in the asphalt will be (relatively) independent of the asphalt modulus. In this case (in practice, thin asphalt surfacings), the asphalt is seen to be operating in a ‘controlled strain’ mode because the tensile strain in the asphalt is ‘controlled’ by the dominance of the stiffness of the pavement sub-structure supporting the asphalt and, hence, is (relatively) independent of the asphalt modulus.

Because a stiff asphalt layer can withstand less applications of a given strain than a soft asphalt layer, in the ‘controlled strain’ situation, fatigue life can be increased by decreasing the asphalt modulus. For the ‘controlled stress’ situation, where the asphalt is providing the bulk of the pavement stiffness, fatigue life can be further improved by using a lower modulus asphalt with a higher bitumen content in the bottom portion of the asphalt where it is subject to tensile strains. In such a manner, the versatile properties of asphalt are best utilised.

Effects of asphalt modulus and its temperature dependence

The dependence of mix modulus on temperature can be very relevant to asphalt fatigue life in locations where temperature variations are considerable. The direct effects that these factors have on fatigue life are indicated – for both the controlled stress and the controlled strain situations can be found in the table below.

Table 1: Effects of asphalt modulus and its temperature dependence

Effect of binder type

Mixes that use conventional binders allow for some increase in mix modulus with increase in bitumen class number, affecting fatigue life. Utilising binders which have been modified by the incorporation of polymers (PMBs) or other binders (e.g. multigrade binders) can lead to considerably improved fatigue lives when tested in the laboratory (Baburamani & Potter 1996). Please be aware that there are no current fatigue relationships available to estimate the in-service fatigue life of mixes with other than standard grade conventional binders.

Effect of temperature environment

Asphalt fatigue is dependent on mix modulus, and this in turn is reliant on temperature. With time, the distribution of load applications can be quite important in determining fatigue life. For example, if all applications of load were applied during times of low temperatures, resulting in different fatigue life. This is then compared to the situation where the loading happens at higher temperatures.

The actual difference depends on the magnitude of the loads, the thickness of the asphalt layer, the pavement composition and the different proportions of traffic loads applied at low and high temperatures.

Below is an infographic summarising factors that affect asphalt fatigue life.