High-RAP Asphalt: Where Sustainable Practice Meets Binder Precision

♻️ Introduction: RAP and the Sustainability Shift

As global and local infrastructure sectors continue to prioritise sustainable construction, Reclaimed Asphalt Pavement (RAP) has become a key strategy for reducing environmental impact and conserving natural resources. RAP involves the reuse of milled or excavated asphalt from existing roads, containing both valuable aggregates and bituminous binder. By reintegrating these materials into new asphalt mixes, the demand for virgin inputs is reduced, directly supporting circular economy goals.

While incorporating small amounts of RAP (typically under 15%) is relatively straightforward, increasing the RAP content presents new challenges. Beyond this point, it’s no longer just about reuse; it becomes a matter of precision binder engineering.

In this blog, we explore what changes beyond 15% RAP, how binder behaviour must be controlled, and what Queensland's Transport and Main Roads (TMR) requires regarding design, approval, and compliance for high-RAP asphalt mixes.

Credit: Queensland Department of Transport and Main Roads

⚠️ The 15% Threshold: Where Recycling Becomes Design

When a dense graded asphalt mix exceeds 15% RAP, the approach must change. The influence of aged binder from RAP is minimal at lower contents, and virgin binder dominates the mix. However, beyond this threshold, the aged binder begins to significantly affect the viscosity, stiffness, and performance of the final mix.

At this point, asphalt production isn’t just about recycling — it becomes binder-blending engineering. The goal is to create a binder phase that performs like a conventional mix, but with a much more complex input profile.

📘 Key Terminology Explained

Before diving further, it's essential to understand the key components of a RAP mix:

RAP (Reclaimed Asphalt Pavement): Asphalt removed from existing pavements, containing both aged binder and aggregates.

Aged Binder: The hardened bitumen within RAP, often oxidised and stiffer due to years of exposure.

Virgin Binder: Fresh, unaged bitumen added to restore flexibility, cohesion, and overall workability.

Rejuvenator: A softening agent sometimes added to reduce the stiffness of aged binder and improve blend performance.

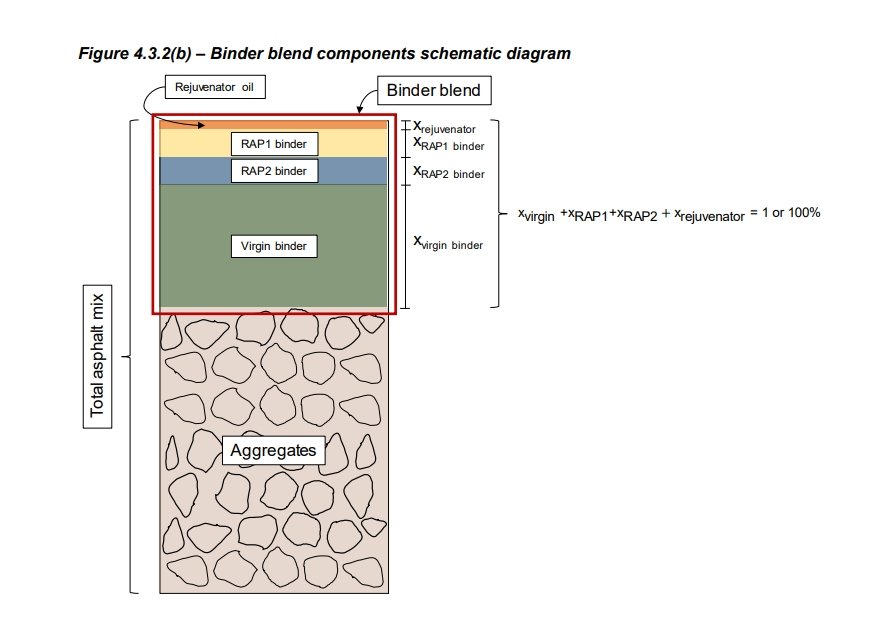

Binder Blend: The combined contribution of aged binder, virgin binder, and rejuvenator, which must meet performance specifications such as viscosity and effective binder volume.

🔧 Assessment Criteria

🚦 Before using >15% RAP on Transport and Main Roads (TMR) projects in Queensland, contractors must obtain formal approval. This isn’t just a checkbox; the approval hinges on demonstrating technical maturity and system robustness.

Proven ability to process RAP to a homogeneous state (particle distribution, binder coating, etc.)

Capability to meet MRTS30 conformance—across mix, binder, and plant performance

📅 All approval requests must be submitted ≥28 days before work commences, with a full supporting information file. The TMR Asphalt Mix Design Registrar assesses risk and reliability across production and design parameters.

📐 Binder Blend Design: The Core Challenge

The binder blend is central to achieving both performance and compliance. As RAP content increases, the proportion of aged binder increases, making it critical to balance the binder phase carefully.

This is particularly important in Queensland, where Transport and Main Roads (TMR) mandates that asphalt mixes with more than 15% RAP must undergo a formal design and approval process. The blend must meet the performance standards outlined in MRTS30 – Asphalt Pavements, especially regarding:

Viscosity limits

Minimum effective binder volume

Layer-specific performance criteria

This shift requires contractors to model binder behaviour, control inputs precisely, and often integrate rejuvenating agents to counteract the rigidity of the aged binder. Binder blend must meet strict viscosity requirements when incorporating 16–40% RAP. Two distinct methods are permitted, each with technical nuance and implications for mix design.

Methods For Binder Blend Viscosity

Method 1 – Virgin Binder Adjustment (up to 30% RAP):

Contractors may adjust the virgin binder class using the specified table, provided the RAP has predictable properties (e.g., 4.1 ± 0.5% binder content) — typically from South-East Queensland profilings.

Credit: Queensland Department of Transport and Main Roads

Method 2 – Binder Viscosity Targeting (16–40% RAP):

Used when more control is needed, or Method 1 isn’t suitable. This method applies if:

RAP content is over 30%

RAP binder content is outside 4.1 ± 0.5%

RAP is from multiple or unknown sources

A rejuvenator is used

RAP properties vary significantly

The contractor opts for tighter binder control

Project or TMR specifications mandate it

Calculation of binder blend viscosity

In high-RAP asphalt mixes, the binder consists of contributions from virgin binder, one or more RAP sources, and possibly a rejuvenator. These components must always make up 100% of the total binder blend, so if one changes, the others must adjust to maintain the right balance and performance.

This process, guided by Austroads TT1817, enables Prequalified Asphalt Contractors (PACs) to:

Precisely control binder viscosity

Meet minimum effective binder volume requirements

Tackle variability in multi-source RAP stockpiles

RAP-rich asphalt is sustainable — but only if binder performance is engineered with purpose, not assumed.

To meet performance specifications and ensure consistency in production, the viscosity of the binder blend must be calculated and controlled, and it starts with knowing your inputs.

👉 According to TMR specifications and Austroads AGPT/T193, the process involves:

Determining the binder content and viscosity of the RAP binder

Identifying the asphalt mix binder content

Calculating the viscosity blending index (VBIᵢ) of each component — RAP, virgin binder, and rejuvenator

Calculating the volume fraction (xᵢ) of each binder in the blend

Using this to determine the overall blending index (VBIᵦ) of the binder system

And finally, calculating the viscosity (μ) of the total binder blend

The flowchart of the binder blend viscosity calculations is shown below:

Credit: Queensland Department of Transport and Main Roads

🧪 What does the Binder Blend Viscosity Process Actually Mean?

Combining binders isn't enough when using high levels of RAP. You need to understand how the aged binder, virgin binder, and rejuvenator interact and whether the final blend meets the required specifications.

Credit: Queensland Department of Transport and Main Roads

The binder blend viscosity process is a structured method to:

Quantify each binder component’s contribution

Calculate how each binder type influences the mix

Determine the final viscosity of the blend

Ensure compliance with MRTS30 for >15% RAP

This ensures the binder behaves as it should — not too stiff, not too soft — and delivers long-term performance.

🌱 Why It’s Worth It: The Benefits of High-RAP Asphalt

Despite the added complexity, the benefits of high-RAP asphalt are considerable:

✅ Reduced use of virgin aggregates and binder

✅ Lower carbon emissions and energy demand

✅ Strong alignment with circular economy principles

✅ Lower material costs and improved resource efficiency

A high-RAP mix design allows contractors to meet both performance and environmental goals—but only when binder engineering is handled with care and technical precision.

Reference

Queensland Department of Transport and Main Roads. (2019). Technical Note 183: Use of high percentages of Reclaimed Asphalt Pavement (RAP) material in dense graded asphalt. https://www.tmr.qld.gov.au